PRODUCT TESTING

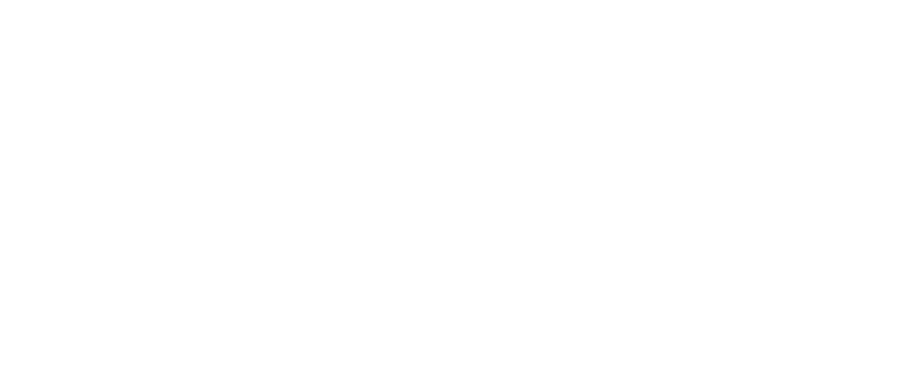

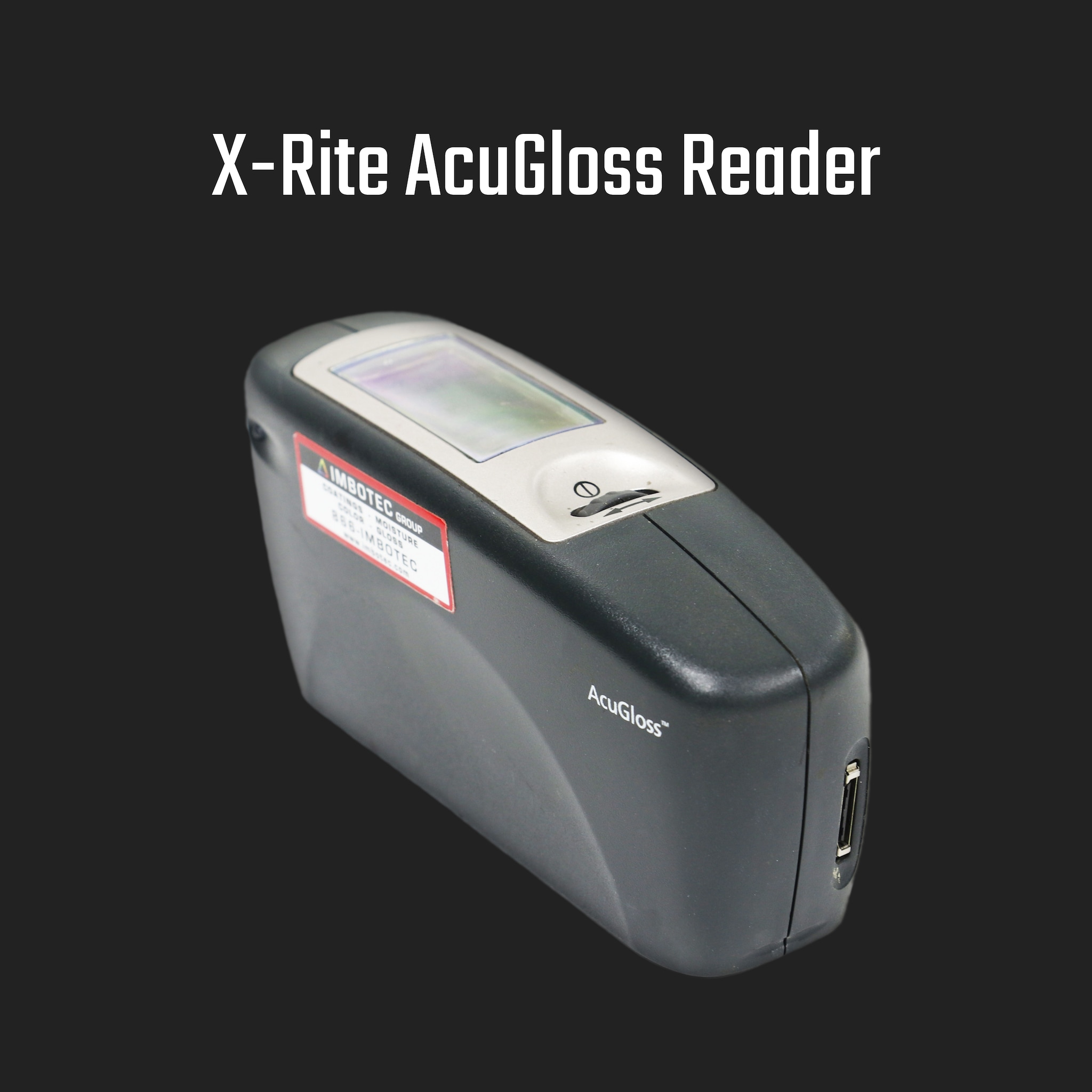

We perform a myriad of tests on our products so that we can say with confidence that we are theindustry's leader in durability, hardness, scratch resistance, flexibility and chemical resistance.

- 250 ION BOND

- 500 BLUEING

- 641 DURACOAT

- 690 PARKERIZING

- 744 GUNKOTE

- 3333 BLACK OXIDE

- 6697 CERAKOTE® CERAKOTE®

Added To Cart

{{ itemJustAddedToCart.product.name }}

Amount:

{{ pricePerUnit }}

/unit

Quantity:

{{ data.quantity.value }}

{{ data.quantity.unit }}

{{ itemJustAddedToCart.product.name }}

Swatches are aluminum panels sprayed with Cerakote for DEMONSTRATION AND COLOR REPRESENTATION PURPOSES ONLY. If you desire a testing sample please contact us at info@cerakote.com If your order contains an "Out of Stock" swatch, we will create that swatch for you, then ship your entire swatch order. This can take up to two weeks.

If all swatches are IN STOCK it will ship in 1-3 business days via 2nd Day Air.

Items are Added to Your Cart